In pipeline project, the correct selection of electric actuated valves is a necessary to guarantee the project’s safety and process. If the electric actuator valve used incorrectly, it will not only affect the use, but also bring unfavorable consequences or serious losses. So, how do we choose electric valves correctly?

Fisrt of all, we need to know what is electric actuator valve?

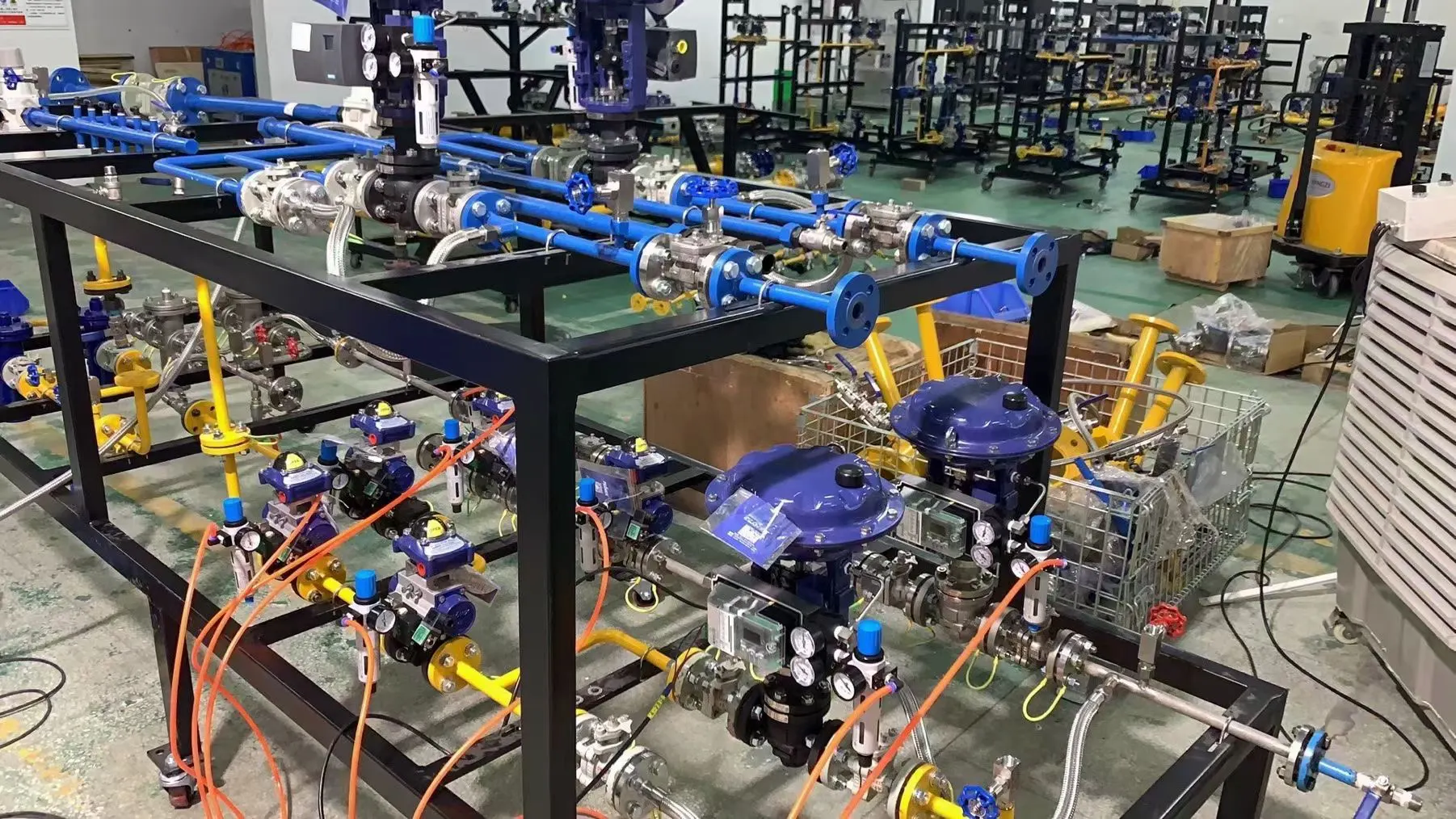

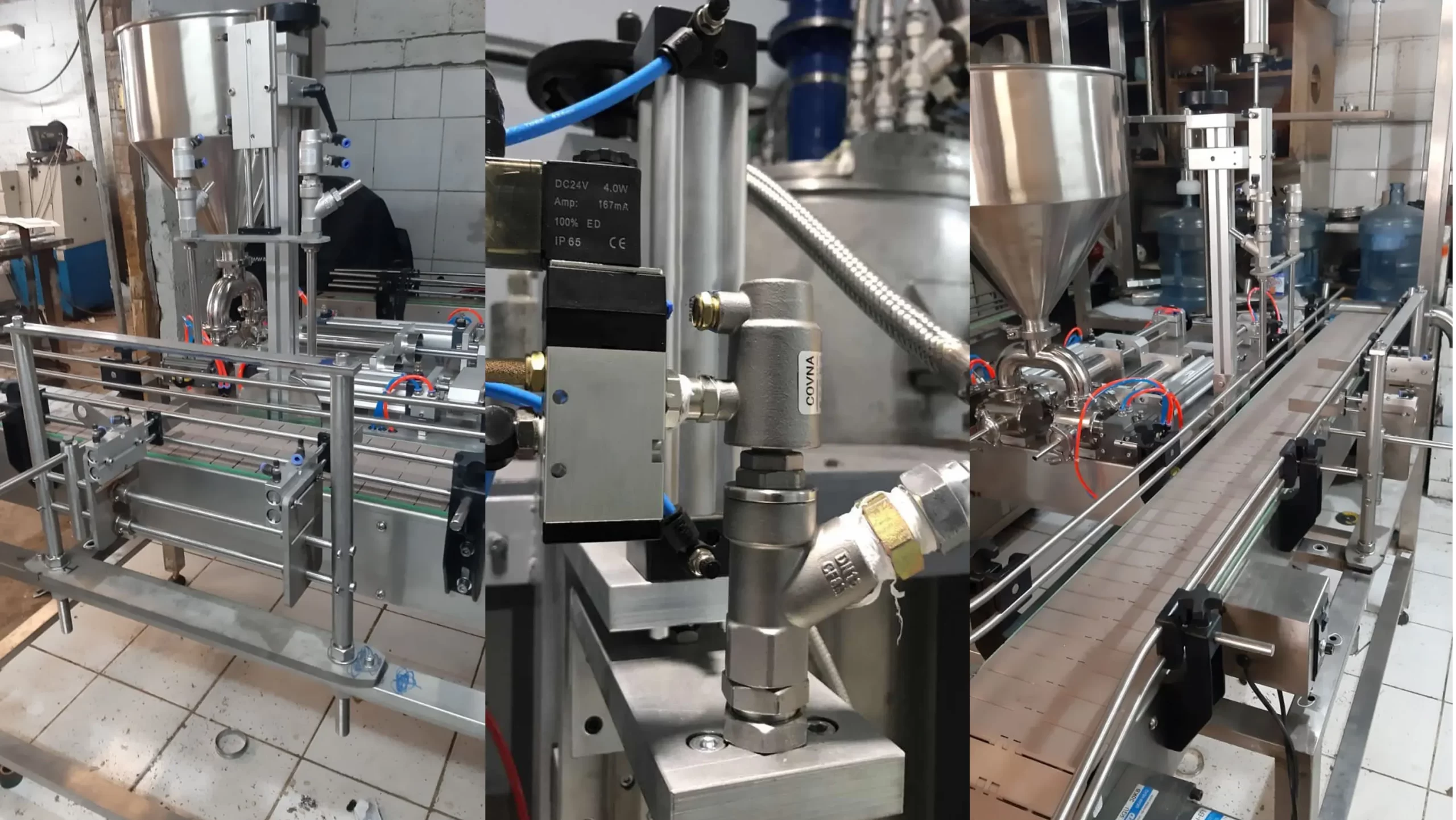

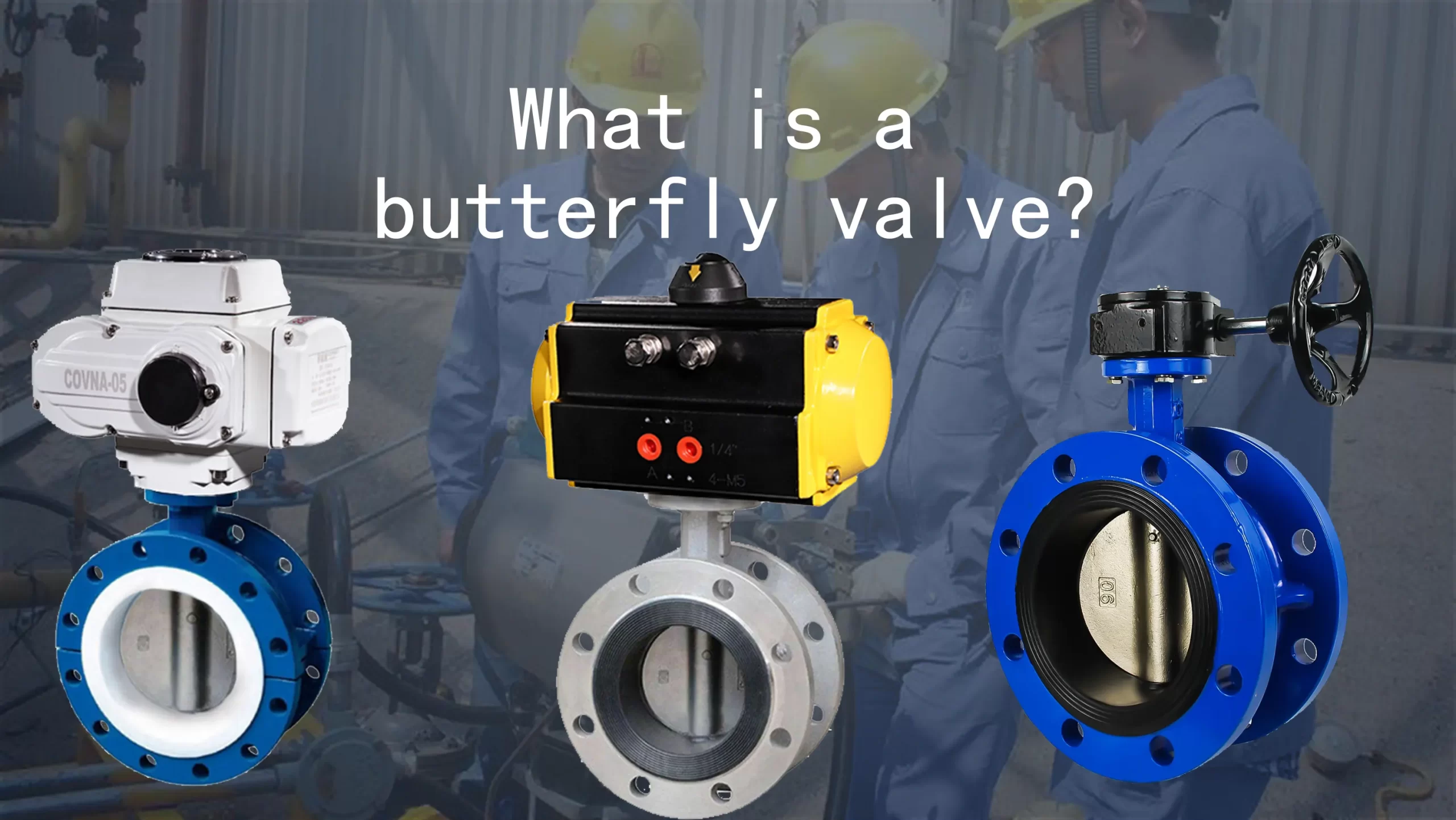

An electric valve actuator is made up of an electric device and a valve. A valve actuator is the mechanism for opening and closing a valve.

Electric actuator valves are usually connected by electric actuators and valves, and become electric actuator valves after installation and debugging. The electric valve uses electric energy as power to motviate the electric actuator to drive the valve, realizing its on-off and regulating action. So as to achieve the purpose of switching or adjusting the pipeline medium.

Notice on choosing the electric actuator valve:

1. Output speed: If the opening and closing speed of the valve is too fast, will easily caus water hammer. Therefore, the appropriate opening and closing speed should be selected according to different use conditions;

2. Control torque: after the specifications are determined, the control torque is also determined. Generally run within a predetermined time, the motor will not be overloaded;

3. Control form: electric actuators are divided into on-off type and regulating type, and the signals of regulating type actuators are also divided into current signals and voltage information numbers;

4. Control voltage: conventional electric actuator voltages are AC220V, AC380V, DC24V, etc.;

5. Operating torque: Operating torque is the most important parameter for selecting electric actuator valve devices. The output torque of the electric actuator should be 1.2 to 1.5 times of the maximum valve operating torque;

6. Electric device: one is not equipped with a thrust plate, and the torque is directly output;

the other is with a thrust plate, and the output torque is converted into output thrust through the stem nut in the thrust plate;

7. Output shaft turns number: The number of turns of the output shaft of the valve electric device is related to the nominal diameter of the valve, the pitch of the valve stem, and the number of thread heads. It should be calculated according to M=H/ZS (M is what the electric device should meet the total number of turns, H is the opening height of the valve, S is the thread pitch of the stem drive thread, and Z is the number of stem threads);

8. Valve stem diameter: for multi-turn type rising stem valves, if the maximum stem diameter allowed by the electric device cannot pass through the stem of the matched valve, it cannot be assembled into an electric valve. Therefore, the inner diameter of the hollow output shaft of the electric device must be larger than the outer diameter of the stem of the rising stem valve. For part-turn valves and dark-stem valves in multi-turn valves, although there is no need to consider the passage of the stem diameter, the stem diameter and the size of the keyway should be fully considered when selecting and matching, so that it can work normally after assembly.

--- END ---