Accidents caused by poor manufacturing quality, poor management, misoperation, etc. are not uncommon. Some serious accidents in the world are caused by valve accidents. Therefore, it is imperative to strengthen the management of valves.

So, how to manage them efficiently? There are some suggestions I’d like to share.

1. Management of technical data

Valve technical data mainly includes national standards and related standards, valve factory instructions, quality certificates, valve installation and construction drawings, valve maintenance, maintenance records, valve daily management cards and valve change records, etc. Complete and complete valve technical data play a multiplier role at critical moments, be aware of the daily maintenance and maintenance and replace aging valves in time.

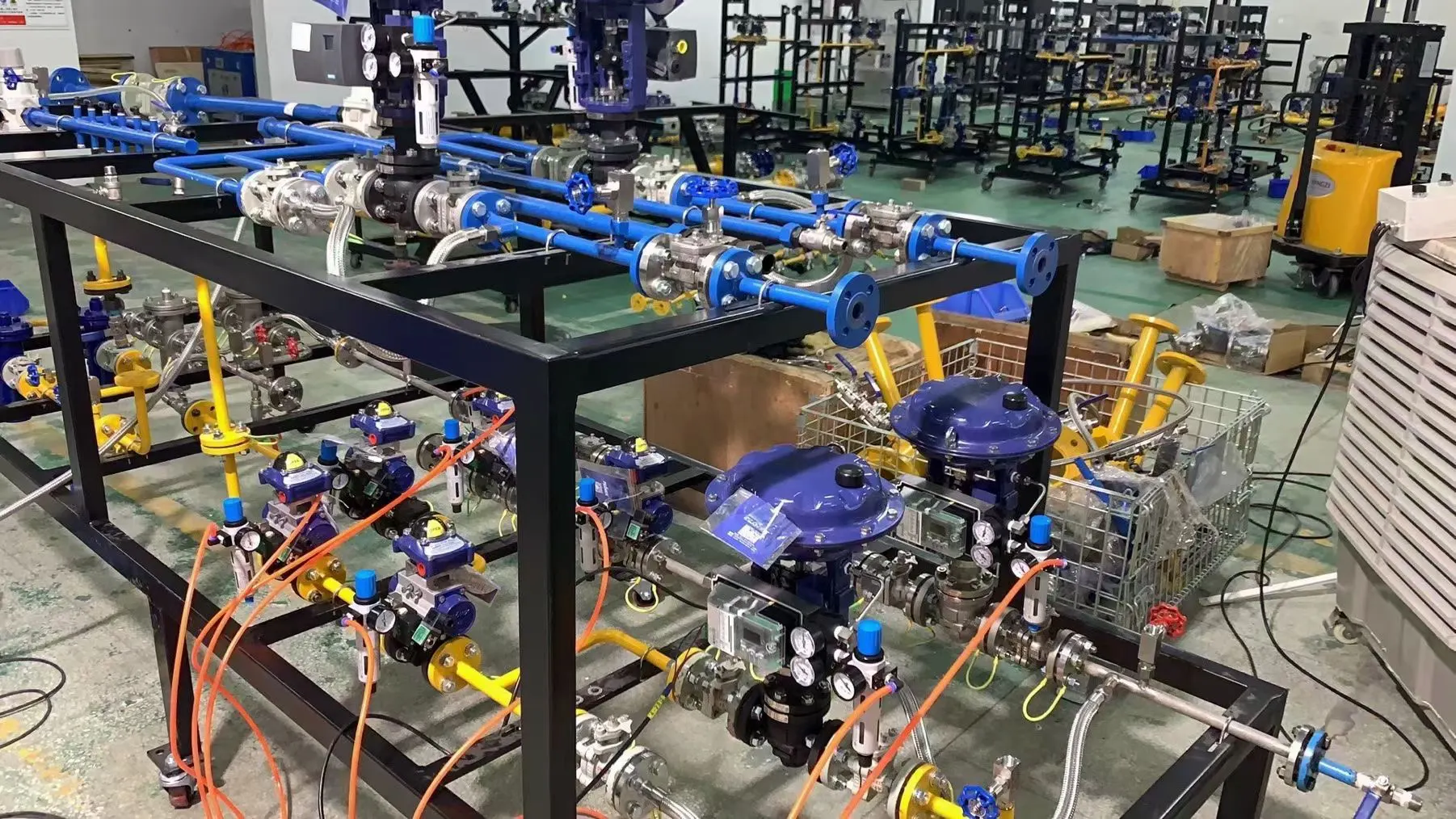

2. Quality management

Including valve quality assurance system, total quality management, pressure test acceptance system, quality control points, personal responsibility system, and handover records, etc.

3. Management of valve maintenance

Including repair and maintenance items, content, period, performance parameters, acceptance criteria, maintenance plan, completion status and maintenance records, etc.

4. Used file management

Including valve model specifications, working pressure, working temperature, use medium and flow direction, factory number, manufacturer and name code of the equipment pipeline, overhaul records and valve replacement records, etc.

5. Design and management of valve wells

The valves set in the buried pipeline network must be built with wells, so as to facilitate the daily maintenance and management of the valves. The diameter of the valve well must be strictly in accordance with the specified size, otherwise, it will seriously affect the daily valve operation. Valve wells should be located on the roadside or green belt as far as possible to facilitate ordinary maintenance and management. The size of the manhole cover must be uniform and strictly in accordance with the requirements of national regulations. If the manhole cover is too large or too small, it will cause safety accidents. This is a problem that valve managers should pay attention to. The determination of the size of the clear space in the valve well should facilitate the replacement of valve parts by valve maintenance personnel. The requirements for disassembly, assembly and replacement operations should be considered without damaging the good wall structure. The management of the valve well includes: the well cover is intact and the road surface is intact; the hole position of the operating valve is accurate; there is no debris and sewage in the well; because the closed space is easy to form in the valve well, it is easy to form hypoxia. The maintenance personnel must ventilate before going down the well. Air exchange and other measures; valve wells should be patrolled regularly to deal with pressure burial problems in time, and problems such as missing or damaged manhole covers should be dealt with in time.

6. Valve failure prevention management

Strengthen the preliminary management, establish a complete valve design, material selection, installation, maintenance, repair, and replacement files.

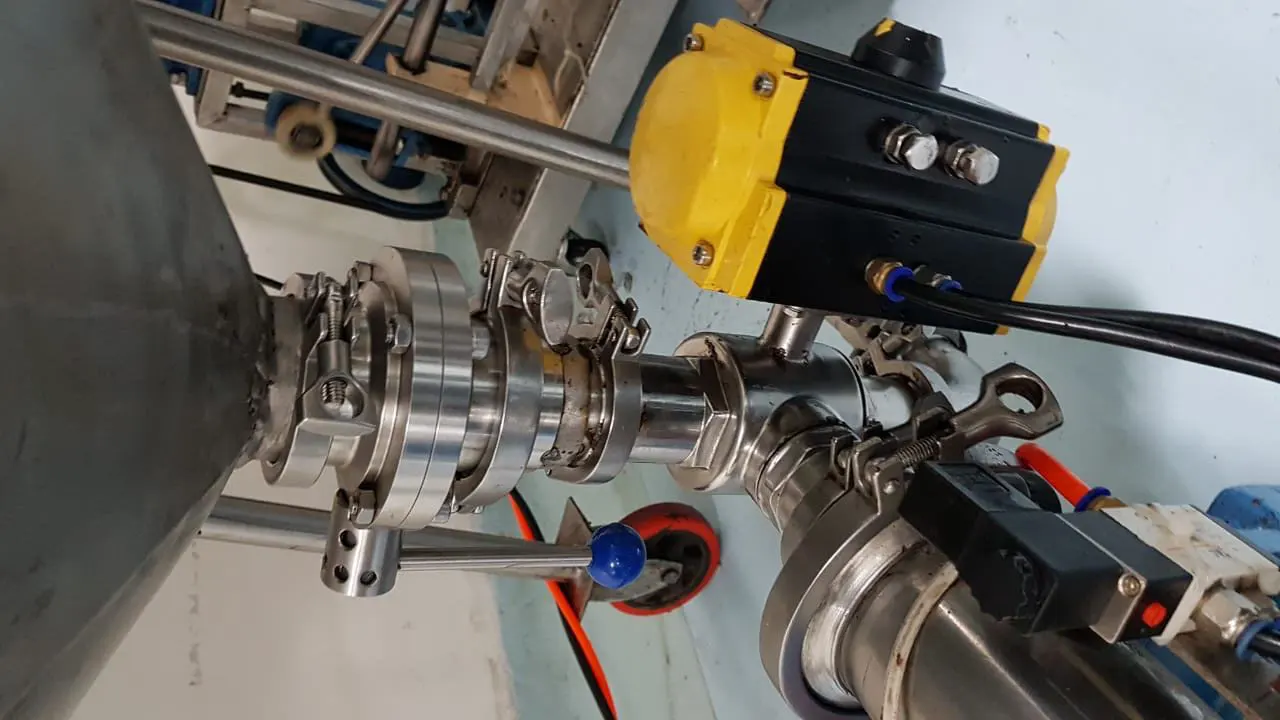

Before the valve enters the pipe network, the strength and tightness test of the valve should be carried out to reduce the possibility of unqualified valves entering the pipe network. The material of the rubber sealing ring has a great influence on the service life of the valve. All the sealing rings are required to use nitrile rubber or EPDM rubber, and resolutely put an end to reclaimed rubber.

The switch operation must control the torque. Use a torque wrench to control the torque quantitatively. Prevent man-made damage to the valve due to improper operation.

Improve material and anti-corrosion requirements.

--- END ---