Pneumatic control valve usage introduction:

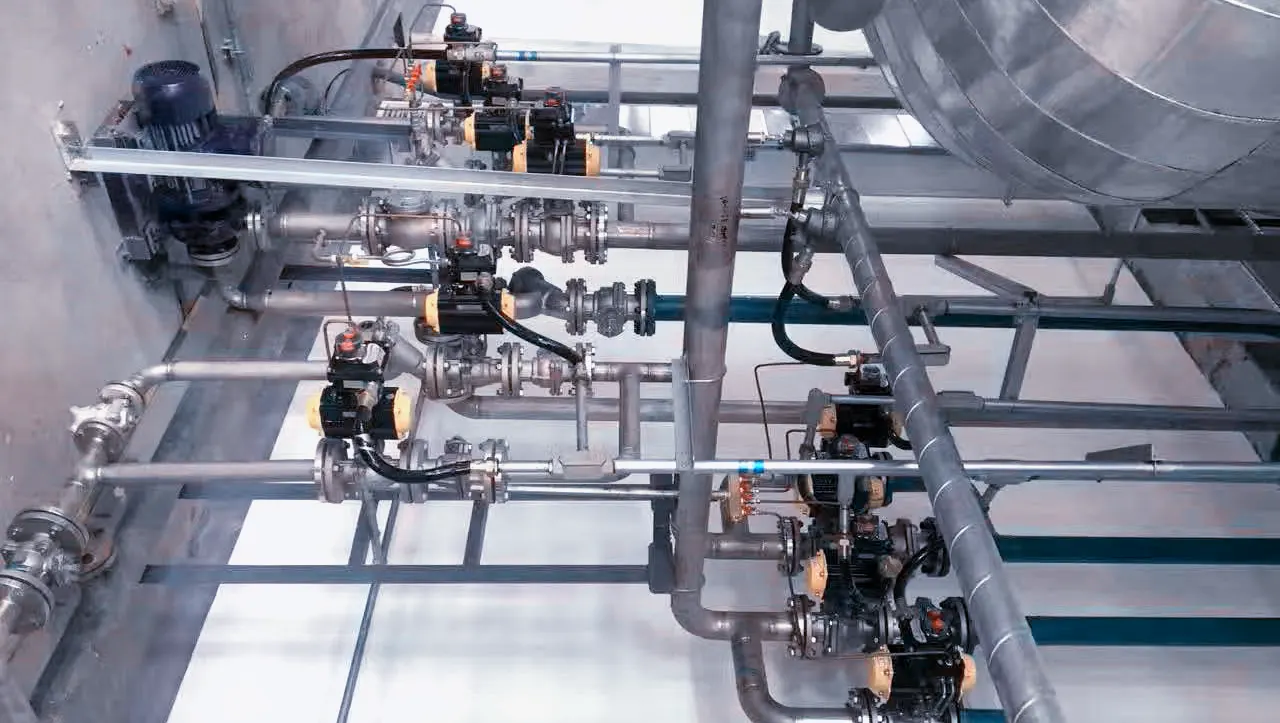

Pneumatic control valve is one of industrial process control instruments widely used in petroleum, chemical, electric power, metallurgy and other industrial enterprises. According to the working principle of the pneumatic control valve, compressed air is used as the power source, the cylinder is the actuator, and the valve is driven by accessories such as electric valve positioner, converter, solenoid valve, and retaining valve to realize the switch or proportional adjustment, receiving the control signal of the industrial automation control system to adjust the flow, pressure, temperature and other process parameters of the pipeline medium.

The use of pneumatic control valve is a right-angle reversal layout. It can be used with a valve positioner to achieve share adjustment. The V-shaped valve core is most suitable for various adjustment occasions. It has a large rated flow coefficient, a large adjustable ratio, and a sealing effect. Good, flexible conditioning function, small size, can be installed vertically.

Working principle of pneumatic control valve:

The pneumatic control valve is composed of an actuator and a conditioning mechanism. The actuator is the thrust component of the conditioning valve, which generates corresponding thrust according to the pressure of the control signal to advance the conditioning mechanism. The valve body is a component of the pneumatic control valve, which directly touches the conditioning medium to regulate the flow of the fluid. According to the flow characteristics of the medium, the structure can be divided into pneumatic single-seat control valve, pneumatic sleeve control valve, pneumatic three-way control valve, pneumatic angle control valve, etc. The following briefly introduces the selection precautions.

Precautions for the selection of pneumatic control valves?

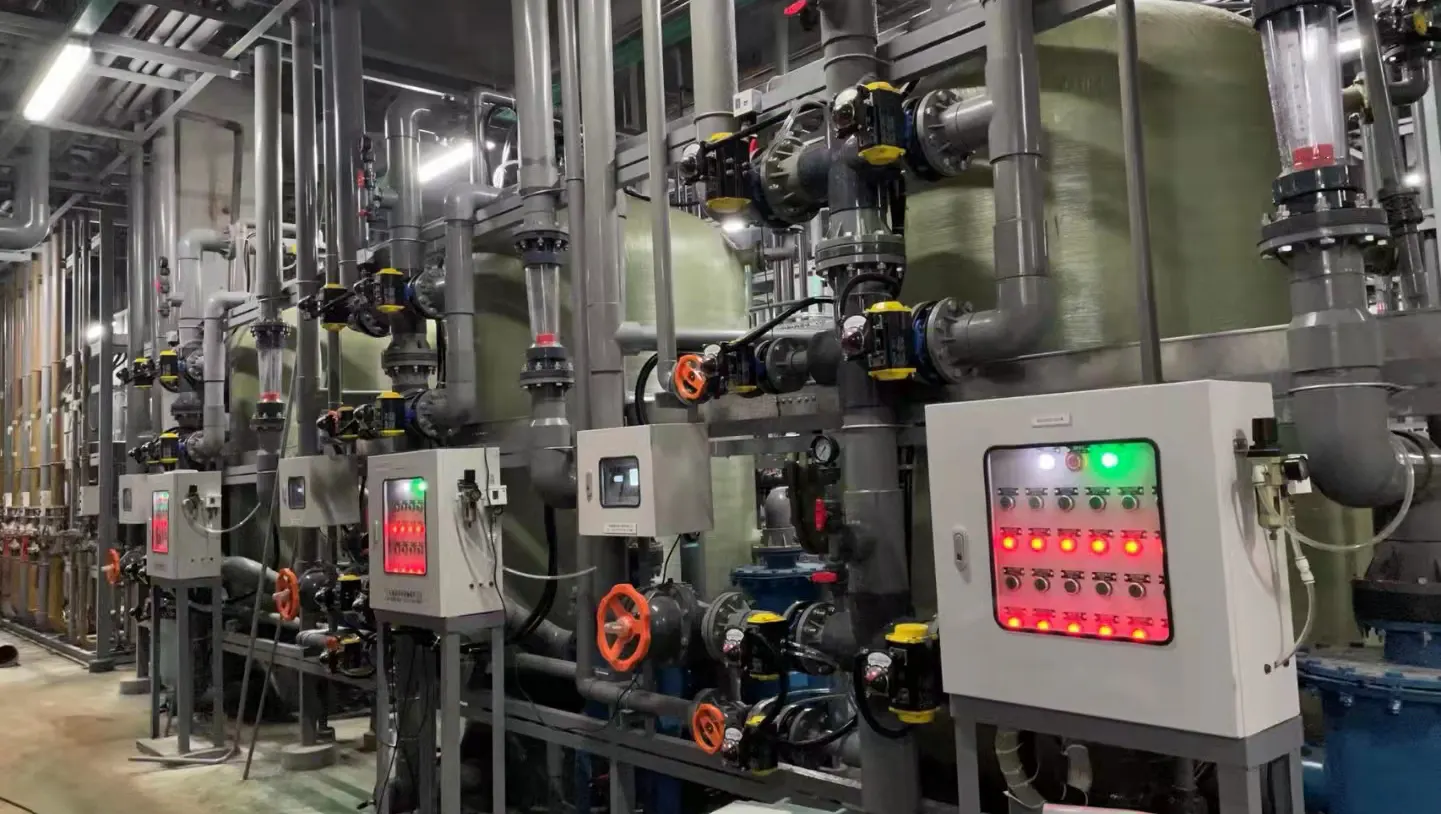

There is not much difference between the pneumatic control valve and the electric control valve fundamentally, but the actuator is different. The former requires a compressed air source, while the latter only requires a power source, which is more convenient. Pneumatic control valves need to be equipped with compressors and other equipment. The advantage is that they have explosion-proof functions, simple maintenance, and low failure rate. Therefore, in the chemical, petrochemical and other industries, the scope of use is much larger than that of electric control valves. Electric valve positioners are divided into mechanical and intelligent pneumatic control valves. The intelligent type has more precise control accuracy than the mechanical type.

According to the different media, the valve body material has different choices accordingly. Commonly used carbon steel, stainless steel 304 or 316, 316L and other materials are corrosive, and fluorine-lined control valve can also be selected. There are also several special pneumatic control valves: low temperature control valve, high temperature control valve, high pressure control valve, small flow control valve and so on. Single-seat control valve is used for working conditions with relatively small pressure difference. Once the pressure difference is relatively large, you can choose sleeve control valve or double-seat control valve, because the leakage of double-seat control valve is relatively large, so if the leakage is required to be relatively small , It is not suitable to choose a double-seat control valve.

The three-way regulating valve is used to combine two fluids into one or divide a fluid into two. For occasions where the pressure difference is particularly large and cavitation or flashing is easy to occur, a multi-stage cage control valve can be selected to reduce the pressure of the high-pressure fluid in stages to achieve the purpose of stable control. In short, users should choose the pneumatic control valve correctly according to their actual needs to achieve good results.

How to solve the the noise and cavitation erosion problems in the use of pneumatic control valves?

1. Mechanical vibration—For example, when the valve core of the pneumatic control valve moves horizontally in the sleeve, the gap between the valve core and the sleeve can be as small as possible or a hard surface sleeve can be used.

2. The mechanical fluidity of the medium-when the medium flows in the pipeline or pneumatic control valve, it will also make noise. We will not elaborate on this situation. Of course, cavitation will also produce noise.

3. Natural frequency vibration-such as pneumatic control valve spool or other components, they all have a natural vibration frequency. For this, the characteristics of the spool can be changed by special casting or forging, and other components can be replaced if necessary. Type of spool.

4. When the cause is the instability of the spool—if the noise is caused by the pressure fluctuation of the fluid caused by the oscillating displacement of the spool, this situation is generally caused by the damping factor of the regulator loop actuator, etc. Re-adjust the damping coefficient or add damping facilities in the direction of spool displacement.

Pneumatic control valve operation:

1. Before using the pneumatic control valve, the joint calibration of the system must be carried out.

2. When the pneumatic control valve is debugged, all bypass valves should be closed and the control valve should be within the normal working range. It is strictly forbidden to adjust the position of the entire valve stem and compression spring.

3. Rain check, the first thing is to check whether the meter connection port is damp, there may be signs of water ingress.

Maintenance of pneumatic control valve:

1. Perform liquidation and lubrication of various components to delay the service life of the pneumatic control valve.

2. The pneumatic control valve should be drained and lubricated on schedule, and the amount of oil in the oiler should be sufficient.

More info pls visit our Alibaba website:

https://automatic.en.alibaba.com/

--- END ---