BLOG

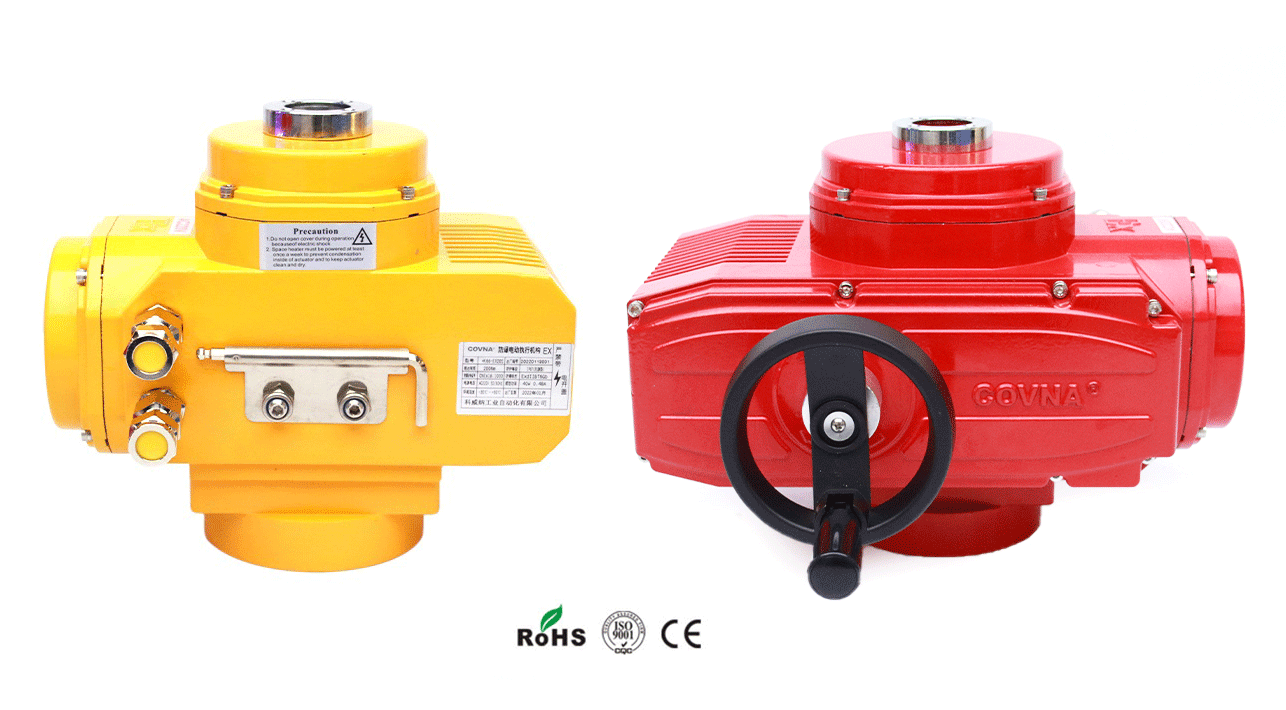

When installing or using the solenoid valve, you may encounter some problems. Below we at COVNA bring you common faults and solutions for low solenoid valves.

- Valve fails to operate

Possible reason and solutions:- Check electrical supply with volt meter. Voltage must agree with nameplate rating.

- Check coil with ohmmeter for shorted1or opened coil.

- Make sure that pressure complies with nameplate rating.

- The valve is sluggish or inoperative-electrical supply and pressure check out

Possible reason and solutions:- Disassemble valve, clean out extraneous matter. The plunger must be free to move without binding.

- If a diaphragm design, check the diaphragm for tears and/or clogged or obstructed bleed hole or pilot orifice Torn diaphragm must be replaced.

- Check all springs. If broken, replace.

- External leakage at sleeve flange or joint between body and cover.

Possible reason and solutions:- Check that the sleeve and lor cover screws are torqued to specifications. If leakage persists replacement of diaphragm assembly or flange O-ring may be required and/or bodies or covers with damaged sealing surfaces may have to be replaced.

- External leakage at speed control device

Possible reason and solutions:- Check O-rings for damage and replace if necessary.

- Internal leakage

Possible reason and solutions:- Disassemble valve, remove extraneous matter, and clean parts in a mild soap and water solution.

- Examine diaphragm sealing surface for dirt. Remove all foreign particles. Examine orifice for nicks. Damaged parts must be repaired or replaced.

- Check plunger return Spring. Replace if broken.

- Chatter or buzz sound when energized

Possible reason and solutions:- Remove power from the coil.

- Inspect the plunger and sleeve for excessive wear or contamination

Tags: solenoid valve

--- END ---