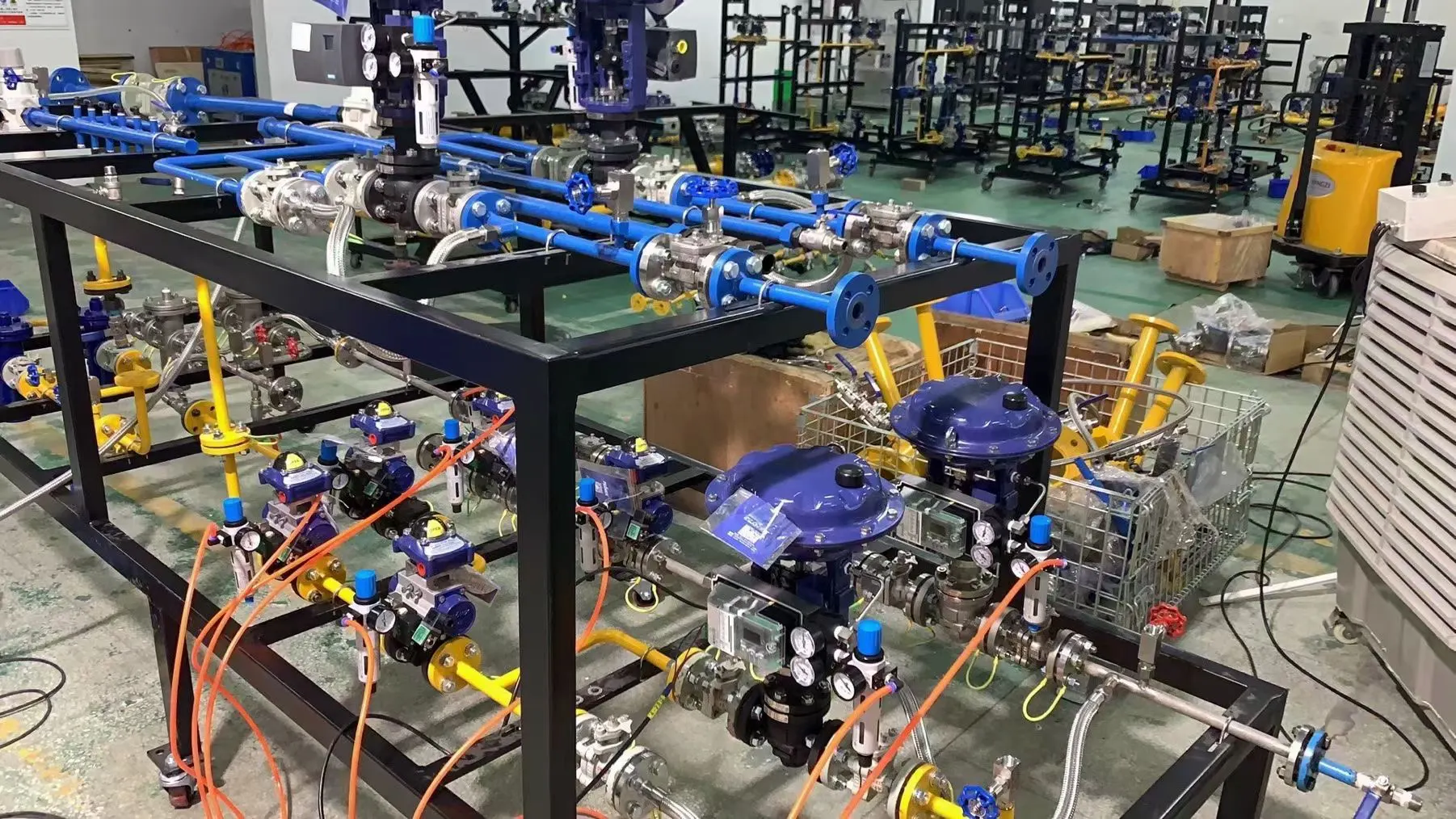

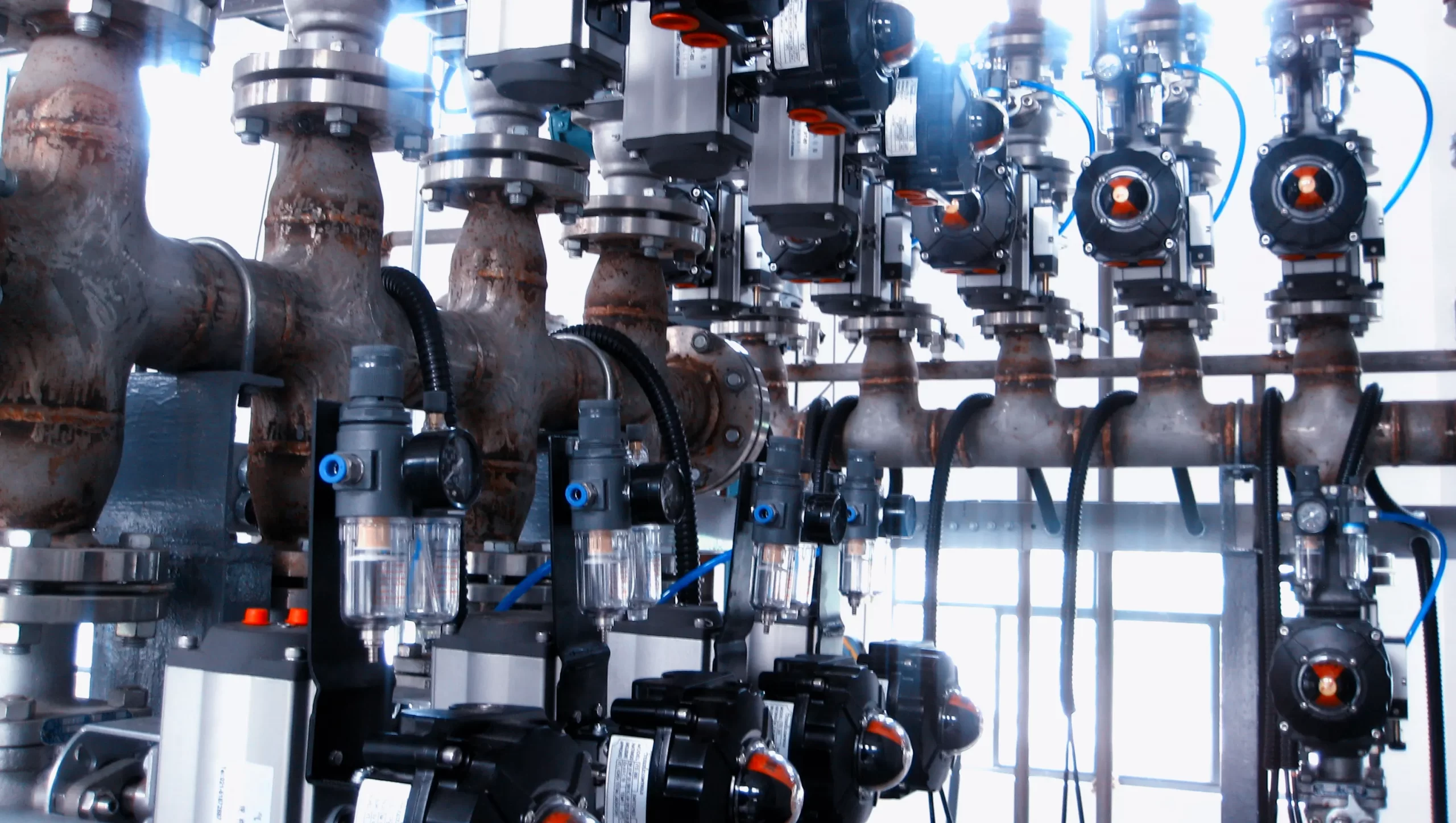

The three-piece pneumatic ball valve is composed of a pneumatic actuator and a three-piece ball valve. The execution speed of the pneumatic actuator is relatively fast, and it does not require workers to do it personally, which saves human resources and time to a large extent. Pneumatic three-piece ball valves are widely used in general working media such as water, solvents, and natural gas, as well as media with harsh working conditions, such as oxygen, hydrogen peroxide, methane, and ethylene.

The working principle of the pneumatic three-piece ball valve: the pneumatic three-piece ball valve only needs to be rotated 90 degrees with air and a small torque can be closed tightly. The completely equal internal cavity of the valve provides a straight flow channel with little resistance for the medium. It is generally believed that the ball valve is most suitable for direct opening and closing, but recent developments have designed the ball valve to throttle and control the flow. The main feature of the pneumatic three-piece ball valve (ball valve) is its compact structure and easy operation and maintenance.

Features of pneumatic actuated three-piece ball valve:

1. The pneumatic three-piece ball valve is simple in structure, small in size, light in weight, and low in fluid resistance. Its resistance coefficient is equal to that of a pipe section of the same length.

2. The pneumatic three-piece ball valve is easy to maintain, the structure of the pneumatic ball valve is simple, the sealing ring is generally movable, and it is convenient to disassemble and replace.

3. It is tight and reliable. At present, the sealing surface material of the ball valve is widely used in plastics and has good sealing performance. It has also been widely used in the vacuum system.

4. Convenient operation, rapid opening and closing, only need to rotate 90° from fully open to fully closed, which is convenient for remote control.

5. It has a wide range of applications, with a diameter ranging from a few millimeters to a few meters, and can be applied from high vacuum to high pressure.

6. When fully open or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium. When the medium passes, it will not cause erosion of the valve sealing surface

--- END ---