What is Electric Butterfly Valve?

The butterfly valve is a rotary valve in which a disk-shaped seating element is rotated 90° to open or close the flow passage

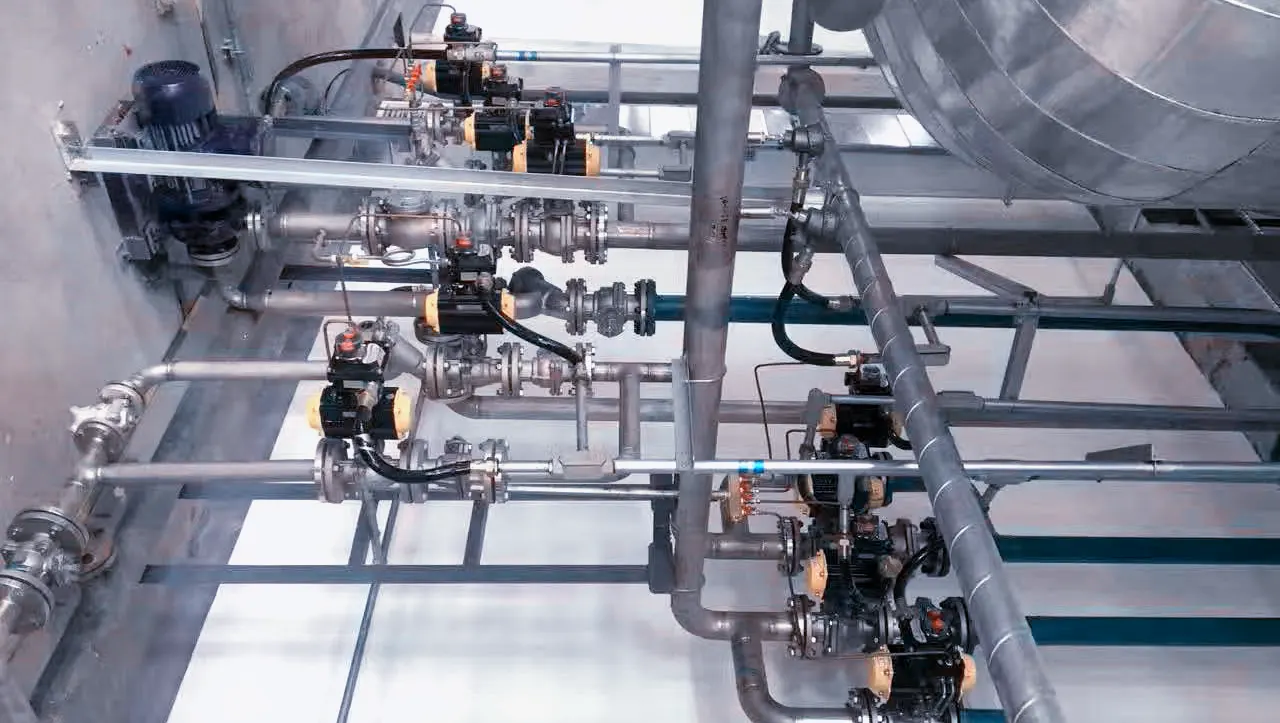

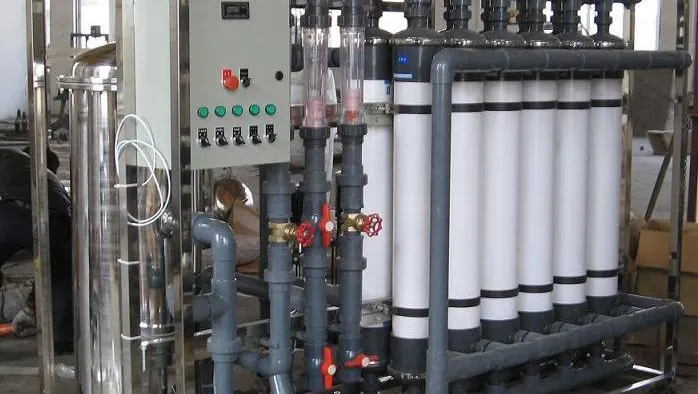

So The Electric butterfly valve belongs to a variety of electric valve and electric modulating valve. Electric butterfly valve connection ends mainly include: flange type and wafer type; electric butterfly valve sealing forms mainly include: rubber seal and metal seal. The electric butterfly valve controls the switch of the butterfly valve through the power signal. The product can be used as a shut-off valve, control valve and check valve for piping systems. With manual control device, once power failure occurs, manual operation can be temporarily used without affecting use.

Application:

They are used in throttling service, particularly where large-size valves with automatic actuators are required. It idely used in textiles, power stations, petrochemicals, heating and cooling, pharmaceuticals, shipbuilding, metallurgy, light industry, environmental protection and other fields.

Electric butterfly valves are suitable for occasions that require flow adjustment. Since the pressure loss of the butterfly valve in the pipeline is relatively large, about three times that of the gate valve, when selecting the butterfly valve, the influence of the pressure loss of the pipeline system should be fully considered, and the robustness of the butterfly plate to withstand the pressure of the pipeline medium when it is closed should also be considered Sex.

In addition, it is necessary to consider the limitation of the working temperature of the elastic valve seat material at high temperature. The structural length and overall height of the butterfly valve are small, the opening and closing speed is fast, and it has good fluid control characteristics. The structural principle of the butterfly valve is most suitable for making large-diameter valves. When the butterfly valve is required to control flow, the most important thing is to correctly select the size and type of the butterfly valve so that it can work properly and effectively.

Structure and Features:

1. It still has stable sealing performance under high temperature and high pressure conditions. Its special sealing system can ensure high sealing performance in various temperature ranges from ultra-low temperature to ultra-high temperature

2. The three-dimensional eccentric sealing system and optimized design make the valve opening resistance small. The sealing surface of the butterfly plate is an upwardly convex cone. When opening, all points on the circumference of the butterfly plate are separated from the sealing ring at the same time, and solid objects are not easy It accumulates on the sealing surface. The valve closing process is completed by the elastic pressure of the sealing ring.

3.There is no phase jam between the butterfly plate and the sealing ring.

4. Sealing performance of the valve is not affected by temperature changes. Double eccentric structure, reliable sealing performance

5. The shaft diameter of the valve stem is sealed with graphite pressed into a sealing ring. In summary, zero leakage is ensured. The metal seal plus zero leakage before, during and after the fire, so it is an intrinsic fire safety type.

6. The butterfly plate adopts a frame structure with high strength, large flow area and small flow resistance

7. The integral baking varnish can effectively prevent corrosion and can be used in different media as long as the sealing material of the sealing valve seat is replaced

8. This valve has a two-way sealing function, and it is not controlled by the flow direction of the medium during installation and is not affected by the spatial position. Can be installed in any direction

9. It has small size, light weight, reliable performance, simple matching and large flow capacity, especially suitable for clean liquids and gases.

10. The electric butterfly valve can transport mud, and the accumulation of liquid at the pipe mouth is minimal.

11. Electric butterfly valve can achieve good sealing under low pressure

Installation and maintenance:

1. During installation, the valve disc should be stopped in the closed position.

2. The opening position should be determined according to the rotation angle of the butterfly plate.

3. For the butterfly valve with bypass valve, the bypass valve should be opened before opening.

4. The installation should be carried out according to the installation instructions of the manufacturer. The heavy butterfly valve should be installed with a firm foundation.

COVNA offers various types electric buterfly valves:

- flanged electric butterfly valve

- wafer type electric butterfly valve

- lug type butterfly valve

- sanitary electric butterfly valve

--- END ---