When you need a valve, maybe you have doubts about what valve to choose? What is the difference between these valves? Here I’ll tell you the difference between solenoid valve and electric ball valve to help you choose the valve.

WHAT IS A SOLENOID VALVE?

A solenoid valve works with an electric current. A solenoid is a wire coil that acts as an electromagnet, and in a valve system, the solenoid controls the current through the valve. In its resting state, a (normally closed*) solenoid valve is closed with a plunger blocking the opening. To open the valve, a simple electric current runs through the solenoid and creates a magnetic field. This magnetic field lifts the plunger and opens the valve.

*The reverse of this would be a normally open valve that remains open until the valve is shut by an electric current.

Manufacturers use solenoids to control fluids, air and gases because the valves can distribute, release, or mix elements with pinpoint control. Since solenoid valves work with a variety of substances, businesses use them in several capacities.

Solenoids require little power, and they are reliable, durable, and compact.

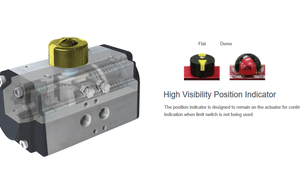

WHAT IS A MOTORIZED BALL VALVE?

Ball valves use motors to rotate a ball with a hole in the center to control flow. When the hole is in line with the flow, the valve is fully open, and when it is turned perpendicular to the flow, it is closed. Most electric ball valves don’t require power to hold position like solenoid valves. Some electric actuated ball valves can be opened or closed manually.

Ball valves work well in situations that involve large volumes of flow. For example, airports use them for de-icing aircraft, greenhouse managers use them for watering greenhouses, and farmers use them for watering large farms. Buildings with fire suppression technology rely on ball valves for opening and closing the sprinkler heads.

Motorized ball valves allow liquid, gas, or air through electric controls. Some have several valves to manage large systems.

PROS AND CONS OF SOLENOID VALVES

Advantage:

- Solenoid valve can be quickly closed or opened

- Due to their simple design, the power consumption is rather low for a solenoid valve.

- Due to the simple structure of the solenoid valve, maintenance is very convenient, and most parts can be recycled.

- The price is cheaper

Shortcoming:

- Can only handle low traffic.

- Solenoids do not have manual overrides, so users must consider water-hammer potential from rapid closing.

- Solenoid valve processing media can not have particles, particles in the media will lead to solenoid valve can not be closed, resulting in leakage.

PROS AND CONS OF MOTORIZED BALL VALVES

Advantage:

- Can handle larger flow rates compared to solenoid valves.

- Will not burn out due to long time power on.

- The flow rate of the valve switch can be adjusted.

- They are easily integrated into automation systems through multiple devices like PCs and even Raspberry Pis.

Shortcoming:

- The switching time of motorized ball valve is longer than that of solenoid valve, generally 2 to 3 seconds.

- Ball valve in the media with particles in the switch will have wear and tear, a long time will appear leakage, and the ball inside is not easy to replace

- Price will be expensive compared with solenoid valve.

FINAL THOUGHTS

In the end, to decide what type of valve to use, you need to understand why you need a valve. If you have further questions or guidance for the correct valves for your project, our valve experts are available by phone or chat on covnagroup.com

--- END ---