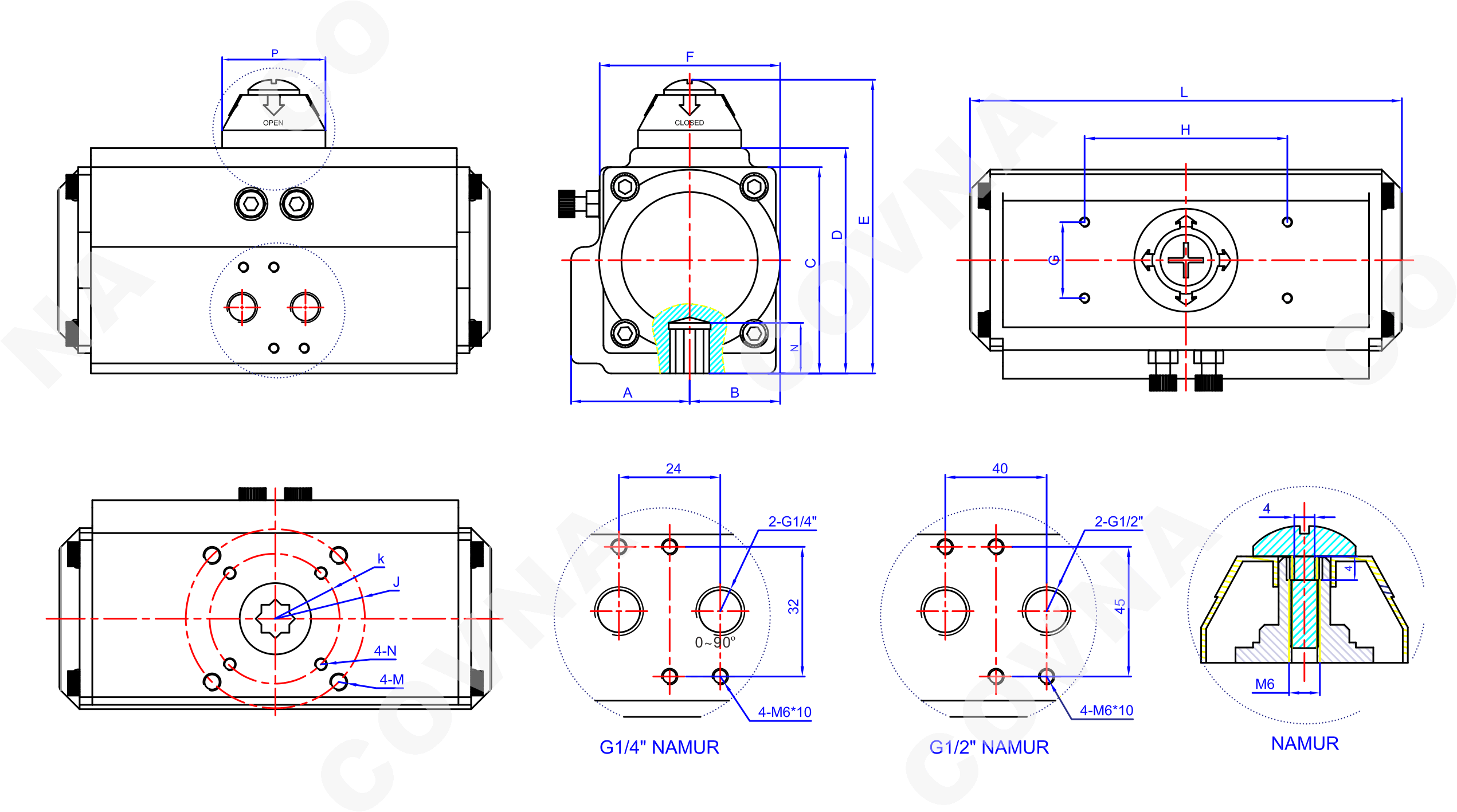

COVNA HK55-3PS-F Series Pneumatic 3 Pieces Flange Ball Valve

COVNA HK55-3PS-F pneumatic flange ball valve, 2 way port configuration, default GB standard, ANSI, JIS, DIN or API 6D is available, double acting standard control mode, single acting is available, 304 or 316 stainless steel body construction, 2.5 to 8 bar input air pressure, minimum 1/2 inch flanged connection, default PTFE seat, resistant to almost all fluids. Suitable for higher operating pressures and temperatures.

- Model: HK55-3PS-F

- Size Range: 1/2" to 4"

- Pressure Range: 1.0 to 2.0MPa

- Material: WCB, Stainless Steel

COVNA 2 Way Pneumatic 3PS Flange Ball Valve

● Features: Long Service Life, Eco-Friendly, Easy Installation, etc

● Actuator Type: Spring Return(Single Acting) and Double Acting

● Rotation: Quarter-turn

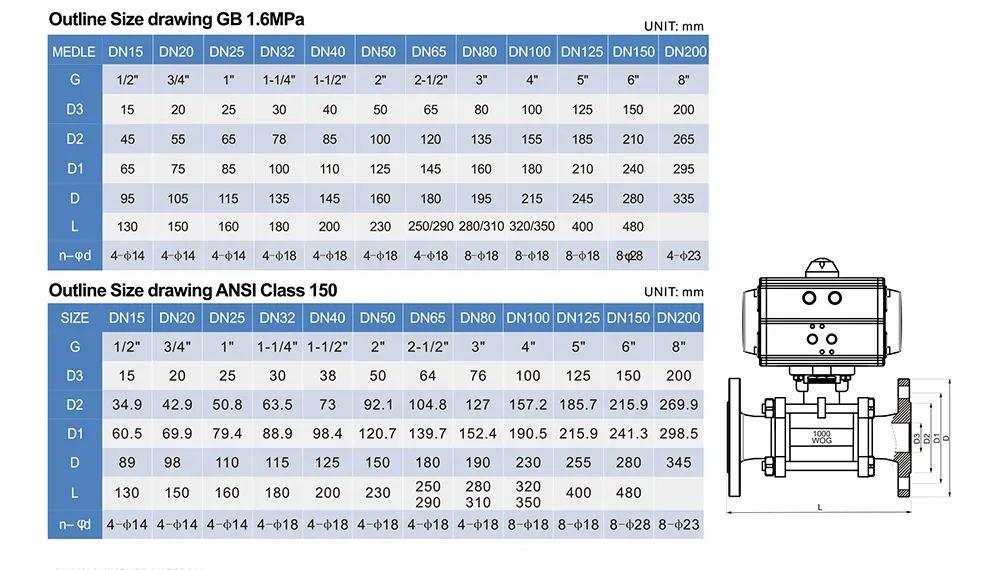

● Applicable Standard: GB, ANSI, JIS,DIN

● Connection Type: Flange End

● Suitable Medium: Water, Oil, Air, Gas, etc

![]()

| Double acting | Air to open, air to close, air supplier failure to keep the current position |

| Single acting N/C | Air to open, interrupt air to close, air failure to close |

| Single acting N/O | Air to close, interrupt air to open, air failure to open |

| Optional accessory | Reversing solenoid valve, limit switch box, air filter reducing valve, positioner, handle manual, lock up valve. |

![]()

| Body | Valve components | ||

| Size range | DN15~DN150 | Sealing material | PTFE, PPL |

| Body material | Stainless steel | Core material | Stainless steel |

| End conection | Flange | Stem material | Stainless steel |

| Operating pressure | 1.6, 2.0 MPa | Applicable media | Water, oil, Gas, Liquid, steam, powder, anti-corrosive base |

| Structure | Floating ball core | ||

– DESCRIPTION –

Pneumatic 3 Pieces Flange Ball Valve for on-off control of water, air, oil and other compatible media. Spring return actuators require a pneumatic pilot signal to change the valve position, springs will return the valve to the normal failsafe position.

Double acting actuators use air pressure to open the valve and air pressure to close the valve. Advantages of air actuated ball valves over other type valves may include: higher flow rates, higher pressures, higher temperatures, wider media compatibiliaty, straight through flow path, reduced water hammer, and use in hazardous environments.