COVNA LDGR Remote type electromagnetic flow meter

Electromagnetic flowmeter is only applicable to measure the flow of conductive liquid, which is wide used in water supply, sewage water measuring, industry chemical measuring etc. The remote type is with high IP protection class and can be installed in different locations for the transmitter and converter. Output signal can pulse,4-20mA or with RS485 communication.

- Model: LDGR

- Size Range: DN15~1000

- Pressure Range: Customized

- Material: Carbon steel

- Introduction

The CONVA LDGR remote water flow meter is a device used to measure the flow rate of water in a pipeline or other water system. This type of meter is designed to be installed at a distance from the point of measurement, allowing for remote monitoring of water usage and flow rates.

Remote water flow meters are commonly used in industrial and commercial applications, where accurate measurement of water usage is important for billing and other purposes. They can also be used in residential settings to monitor water usage and identify leaks or other issues.

One of the key benefits of a remote water flow meter is that it allows for real-time monitoring of water usage. This can help to identify leaks or other issues early on, allowing for prompt repairs and reducing the risk of water damage or other problems.

Another advantage of remote water flow meters is that they can be integrated with other systems, such as building automation systems or water management software. This allows for more efficient management of water usage, as well as improved tracking and reporting of water consumption.

When selecting a remote water flow meter, it is important to consider factors such as accuracy, reliability, and ease of installation. It is also important to choose a meter that is compatible with the specific type of water system being monitored.

- Specification

| Product | Electromagnetic flow meter |

| Model | COVNA LDGR |

| Diameter nominal | DN15~DN1200 |

| Nominal pressure | DN15 – DN250, PN ≤1.6MPa; DN300 – DN1000, PN ≤1.0MPa; DN1200, PN ≤0.6 MPa; Higher pressure can be customized |

| Accuracy | ±0.5% F.S. (Flow speed > 1m/s); ±0.5% F. S. ±2mm/s (Flow speed <1m/s) |

| Liner material | Neoprene (CR), Polyurethane (PU), PTFE (F4), PFEP (F46), PFA |

| Electrode material | 316L Stainless Steel, Hastelloy C, Hastelloy B, Ti, Ta, Pt |

| Medium temperature | Neoprene: -10…+60℃ Polyurethane: -10…+60℃ PTFE/FEP: -10…+120℃ PFA: -10…+180℃ |

| Power supply | 85-245VAC,50/60Hz, 22VDC-26VDC |

| Electrical conductivity | Water min.20μS/cm;other medium min.5μS/cm |

| Structure type | Compact type, Remote type |

| Ingress protection | IP65 for converter, IP68 for sensor |

| Product standard | JB/T 9248-1999 Electromagnetic Flow Meter |

- Measuring principle

Mag meter works based on Faraday’s law, and measure conductive medium with conductivity more than 5 μs/cm and flow range from 0.2 to 15 m/s. An Electromagnetic Flowmeter is a volumetric Flowmeter that measures the flow velocity of a liquid through a pipe.

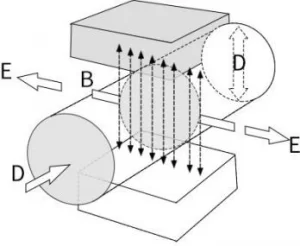

The measurement principle of magnetic flow meters can be described as follows: when the liquid goes through the pipe at the flow rate of v with a diameter D, within which a magnetic flux density of B is created by an exciting coil, the following electromotive E is generated in proportion to flow speed v:

E=K×B×V×D

| Where: E-Induced electromotive force K-Meter constant B-Magnetic induction density V-Average flow speed in cross-section of measuring tube D-Inner diameter of measuring tube |

|

- Application

Electromagnetic flowmeters have been used throughout industries for more than 60 years. These meters are applicable for all conductive liquids, such as: Domestic water, industrial water, raw water, ground water, urban sewage, industrial wastewater, the processed neutral pulp, pulp slurry, etc.