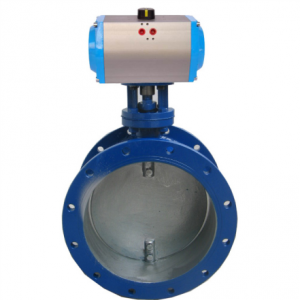

Soft Seat Ductile Iron Double Flanged Air Actuator Control Butterfly Valve

COVNA Pneumatic fluorine lined butterfly valve uses the fluorine lined plastic lining butterfly plate with the spherical sealing surface and the silicon rubber gasket at the base of the valve seat to adjust the sealing performance of the valve; the valve has the advantages of light operation, tight sealing performance and long service life; it can be used to cut off or adjust the flow quickly

- Model: HK59-D-CF

- Size Range: 2''~16''

- Pressure Range: 1.0MPa to 6.4MPa

- Material: Cast Iron

Pneumatic Operated Wafer Type Fluorine Lined Butterfly Valve with worm gear

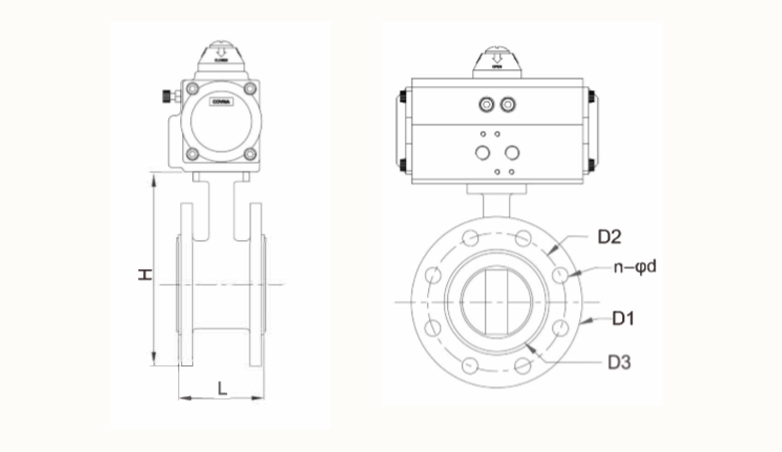

It is suitable for occasions requiring reliable sealing and good regulation characteristics. The valve body adopts the split type, and the sealing at the present end of the valve shaft is controlled by adding fluoro rubber to the rotating base surface between the butterfly plate and the valve seat, so as to achieve compact product structure, beautiful appearance, reasonable process and reliable performance. To ensure that the valve shaft does not contact with the fluid medium in the cavity, it is very convenient to replace the valve shaft, and the valve can be completed without detaching the pipeline. The products are widely used in the transportation of liquid and gas (including steam) in various types of industrial pipelines, especially in the use of corrosive media such as sulfuric acid, hydrofluoric acid, phosphorus, acid, chlorine, strong alkali, aqua regia and other media with strong corrosion

![]()

| Double acting | Air to open, air to close, air supplier failure to keep the current position |

| Single acting N/C | Air to open, interrupt air to close, air failure to close |

| Single acting N/O | Air to close, interrupt air to open, air failure to open |

| Optional accessory | Reversing solenoid valve, limit switch box, air filter reducing valve, positioner, handle manual, lock up valve. |

![]()

| Body | Valve components | ||

| Size range | DN50~DN400 | Sealing material | PTFE, PPL |

| Body material | Stainless steel | Core material | Stainless steel |

| End conection | Wafer, Flange | Stem material | Stainless steel |

| Operating pressure | 1.0MPa to 6.4MPa | Applicable media | Water, oil, Gas, Liquid, steam, powder, anti-corrosive base |

| Structure | Midline Structure/ A-type | ||

![]()