Gearbox Operation

Gearbox Operation is the one of the Driving Method of valves. Owing to the high gear rate, this kind of valve has the advantages of large output torque, easy operation and so on. They are widely used in rotary valves. The gear formed by the self-locking mechanism is suitable for triple offset valve which needs a torque seat. Turn the handwheel clockwise to close the valve and counterclockwise to open the valve.

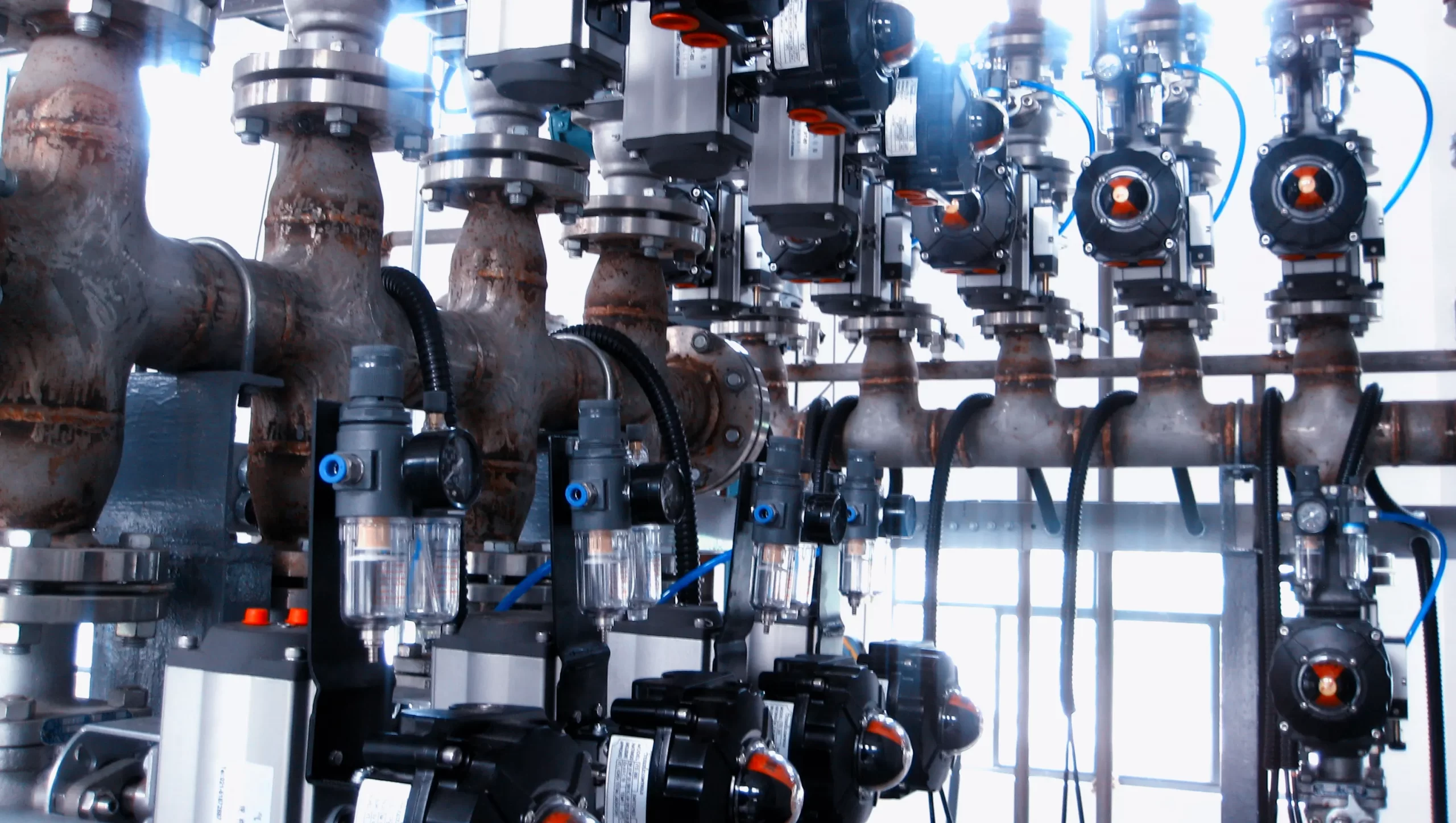

Electric actuator operation

The valve is operated by electrical signals from the motor directing open, close or stop halfway. Electric motor actuators are mainly used for large size or high pressure valves because they have more torque than pneumatic actuators.

This valve has the advantages of simple wiring and quick response. What’s more, remote controls are optional, so valves can be used in hazardous or difficult-to-access limited spaces.

Air pressure operation

This kind of valve is actuated by a air pressure signal, usually 3-8 bar. There are two types of operation: single acting and double acting.

The single acting actuator is separate into full closed and full open type according to the spring acting direction. It is safe and easy to operate and is very useful for control valves.

In addition, the structure responds more sensitively than the electric motor or hydraulic actuator. Double Acting actuators comply with LCM standard with air regulators, solenoid valves and piston indication types. It is well known that LCM is able to meet any customer’s needs.

Double acting and single acting actuators have horizontal opposed double cylinders and are equipped with piston guides to ensure precise contact between rack and pinion at any pressure. The double acting model is similar in overall dimensions to the spring return model.

--- END ---